Most go kart people when they come across raw materials are looking at anything and everything that they can grab from wood, to flat pieces of metal, to the tubing, it doesn’t matter if it’s round square or angle iron.

The question comes across:

“Is angle iron strong enough? Or is it absolutely necessary to use tubing? “

Well the answer to that question actually lies in how thick the angle iron is, the dimensions of the angle iron, and also the dimensions of the tubing itself and where you are putting it.

Angle Iron Vs Tubing

Angle iron is very useful. It’s pretty basic. It’s easy to make. It is relatively cheap and can be more readily available than tubing.

Tubing however is more aesthetically pleasing and also has torsional characteristics and tensional characteristics(cross section area in otherwords) that angle iron does not have.

An angle iron go kart is possible, if you look on the internet you’ll find gokart made out of angle iron. But one of the issues about it is that it tends to not look is pretty and it may actually end up being heavier because you are not using your cross sectional areas as efficiently.

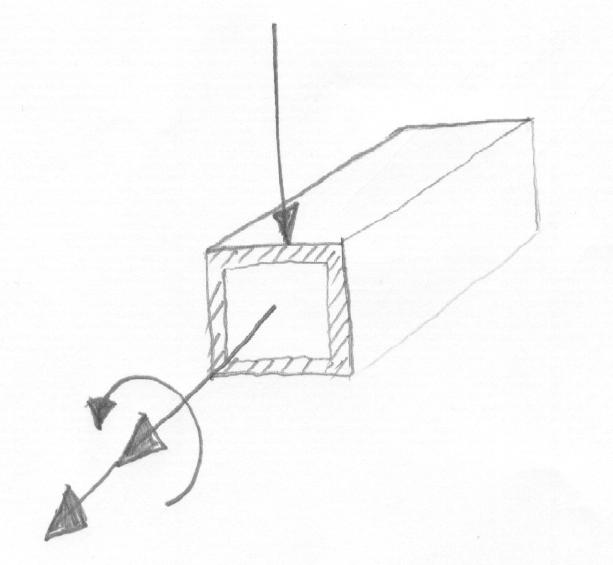

Tubing is a more efficient design, because you have more cross sectional moment of inertia available, so you can maximize the design by minimizing weight.

Fastening

The angle iron has an advantage in that it can be bolted together more readily than tubing. Tubing tends to crush, where as angle iron can be bolted quite nicely together and pull relatively well together.

Both can be welded reasonably. Angle iron tends to come in CQ grades whereas tubing can come and higher grades.

Weight to Strength Ratio

Angle iron, basically is heavy, (heavier if you will per unit length per unit strength) and the one disadvantage is from a buckling standpoint.

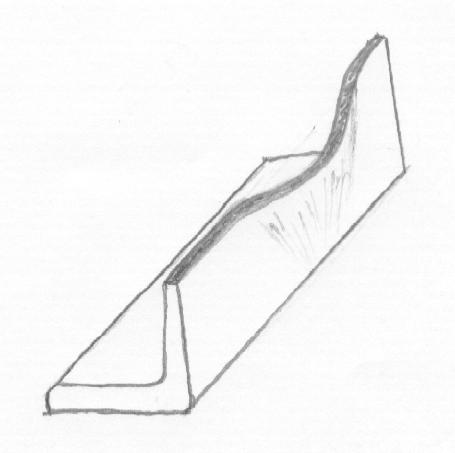

If you ever get into a bending situation, angle iron will tend buckle the top rail (the top section of vertical material) because it is not designed to handle the load, in buckling so much.

Whereas the tube can handle buckling better because it has the whole vertical section supported.

In the figure below the top rail is buckling as the load is bending the angle iron. The Go Kart Building 301 and 401 discuss the nature and what to look for from a calculations standpoint of different cross sections, ie angle iron.

So in order to resist buckling you need to have members the resist that go across that act as buckling nodes and the prevent the part from buckling.

So you will have to have more cross section or supports if you are in a situation where buckling may be an issue. Or you may have to double up the angle iron with another set of angle irons to transfer the load effectively.

So in general, just in a general speaking, angle iron tends and not be as strong from its from a tosional-deflectional standpoint.

If angle iron is all you have I would not steer you away from it, but I would tend to steer you towards a squarish or a roundish tube.

Square Tube Versus Round Tube

Now square tubes verses round tubes, that’s a debate that goes on out there. A square tube actually has a more ability to carry the load and it actually a has a bigger area to take the load, and so it is better in stress than a round tube.

The round tube is more an aesthetic material. It gives you more pleasing lines, it looks cleaner, but from a strength standpoint it is not the most ideal.

Strength and Manufacturability of Square Tubing

Square tubes have more strength and from a manufacturing standpoint. You can actually have higher variables as far as making it. It is easier to mate two parts together, easier to cut angles or to put in a vice. Easier to locate. Your chances of getting your cuts off our much, much less than if you are using a round tube.

With a round tube you have to be very conscious of the orientation of your cuts. You have to mark the tubes, make sure it is in the right axis when you cut them. Whereas a square tube it is much, much more forgiving. Just throw it in a vice and mark it, cut it.

Settle The Question: Angle Iron or Tubing?

So the question was posed in the beginning “Angle iron or tubing?” I would strongly suggested that you use tubing. And that if you have to, use angle iron.

If you are in a light duty loading situation and you just need some metal there, angle iron is very useful for instance as a bracket.

I used angle iron to hold a muffler on a go kart. Basically it served well because it filled the gap between square and round. I just lay the angle iron onto the muffler tube, then welded it on. I then drilled a hole in one side of the bracket and then drill it into the tube on the frame. The angle iron

then supports the muffler to the frame.

Angle Iron Uses

So angle iron tends to have more use in bracketry. Bracketry like seat brackets, holding small parts, putting hinging devices on it, versus trying to make a whole go kart out of it.

There are different sizes of angle irons obviously, and different thicknesses. As far as getting angle iron or tubing refer to the manufacturing sites in your yellow pages or on the internet. You should be reasonable prices, I have a place around my area where you can get tubing whatever size, or even angle iron for relatively cheap and just through it in the back of my suburban and off I go.

You can get it in 10 foot lengths. They will cut down 20 footers (that is the standard size), for me, and I am able to start my project for basically around 40 to 50 bucks.

Where Can I Buy The Tubing or Angle Iron For My Go Kart?

This is the place that I buy stuff from…..