This is a typical proposed simple drive line for a vertical engine. This article will discuss why this system will not work. Put simply the ratio is way wrong and the belt will smoke.

Question: Can a simple pulley and twisted belt drive system work on a go kart for a drive system?

Answer: No, the belt will slip, and there will be tracking problems.

The answer seems simple enough, the belts slipping and belt tracking, but there is more than meets the eye here.

First off, if we run through the calculations, presented in our Go Kart Building 203 course you will discover that the following drive system will smoke the clutch.

Example: Typical Go Kart Drive Requirements

– 1.75 inch Drive Pulley

– 5 hp Engine

– 7.5 Inch Drive Pulley

– 12 Inch Wheel

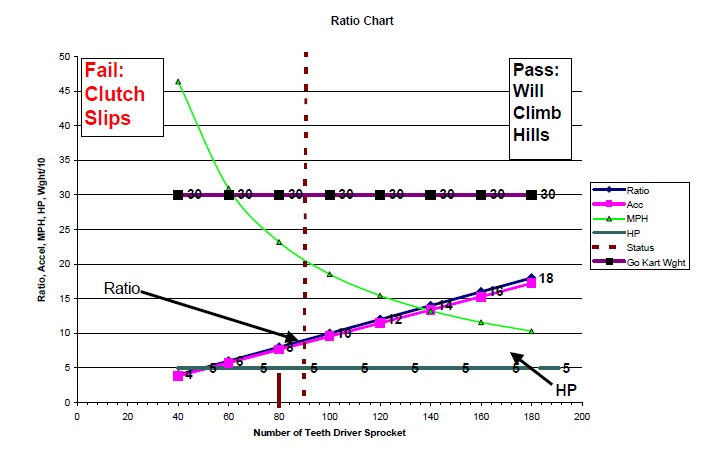

– 325 lb go kart

The following chart shows that the go kart drive line characteristics. First it is showing that the ratio of 9:1 will make the belt smoke and the engine to stall. The go kart will not move very well without a push at any ratio below 9:1. Secondly, the ratio must be above at least 10 or even 11:1 to get a decent running go kart that is not constantly smoking belts.

What you will discover is that you will not be able to get a pulley large enough to satisfy the over all ratio. You will need to get a pulley that is larger than the rear wheel. In fact, just to get to the smoking point of the belt, you will need to have a pulley that is 15.75 inches in diameter.

This chart is from the Go Kart Building 203 Course. The chart is showing the profile of a 5 hp 300 lb go kart drive line system. To the far left the clutch will smoke and the go kart will go backwards. The engine may even stall or quit. The vertical line shown is where the clutch will start to grab and the go kart will go forwards, probably with a little help though. The farther to the right the better the accelleration and less clutch or belt problems.

So you will be forced to deal with drive reduction alternatives at the outset, just to get the go kart to drive.

So as you can see, I call it a “goofy twisted belt drive” because it is not realistic, it will smoke the belts, and not allow the go kart to go anywhere anyway. It may be simple, but is does not take into account the fact that the engine and belt combination will not work together.

In case you are thinking I am saying that twisted belt drives are not plausible, I am not, I am just saying that this particular drive line is not going to work.

In the Go Kart Building 202 course we go into details on how to use a vertical engine, while not using this “goofy twisted belt drive layout” but using a system that works very well, and is quite durable.

As a side note: there are two other major issues with the layout simple layout proposed, first when using a small pulley and a large pulley in a twisted belt drive layout is tracking. The belt has a hard time finding the small belt, especially when the engine drive is slacked, the belt tends to hop the smaller pulley. And vice versa, when the engine is romped on, the belt tend to jump the larger pulley on the slack side, as the belt is suddenly stretched and slacked. The slack section tends to hop out of the larger pulley.

And finally, the smaller pullies generate a lot of heat energy when high horsepower is used. The small pulley cannot dissipate the heat readily and tends to burn the belt, or even melt the belt. It is not uncommon on our wood go karts for example to burn through a belt in a summer. Belt drives work best if the belt is just transferring power smoothly and not being required to be a clutch, or have sudden on and off engagements.

An example of belts being used for extended periods of time are lawnmower deck belts. As long as the belt is just transferring load, and not being required to slip and then engage, the system will work pretty well.

Again, in our Go Kart Building 202 course we have a rock solid drive line that will not break down easily and requires minimum maintenance. That means, nothing is overheating or breaking down in the system.