First of all there are logistical things to consider.

- Motor Size

- Weight

- Person Size

- Acceleration and Top Speed Expectations

- Component Strength

Many of us remember the little chain saw size motors that were used to engage the front tire on a bicycle. These units could make a bicycle go about 15 miles per hour. The over all weight of the system (including the bike and person) was about (120+50) = 170 pounds (which is pretty light compared to a full blown go kart). Frequently the bike had to be pedal started, so that a speed was reached prior to the motor engaging. (This is a critical criteria for the overall performance characteristics of the go-kart, because go karts typically are not going to be push started. They should start from a stop by themselves.)

A bike also has a different construction for mounting the wheels than conventional wagons or buggies. The axels are held in place from both sides of the wheel.

Envision trying to hold onto a bicycle wheel with one hand. It is nigh unto impossible!

Now use both hands. The wheel is very manageable. What you are experiencing is a torque moment that is being exerted through the axel into the one hand. The moment, or torque is very high. In fact, if you were to take into account a 60 pound side load (due to a cornering situation) the axel itself would see a load that could bend the bolt easily.

In order to use wheels off of a bike, the loading must be kept low, or the parts need to be upgraded to handle the higher loads.

The picture below shows a conventional front wheel off of a mountain bike. The second picture shows a wheel off of a bugger (or a bike trailer: a small child can be pulled behind a bike in one of these).

Above is the mountain bike spindle, and then in comparison, the Bugger spindle or axel shaft system.

Calculating the Stresses in the Shafts

Below is the calculation that determines the stresses in the axel shaft:

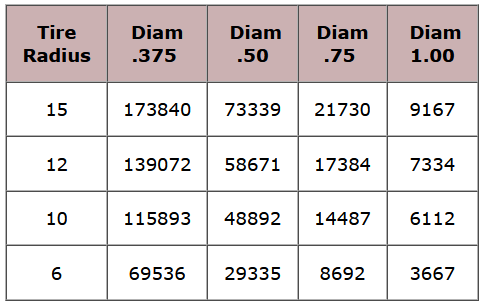

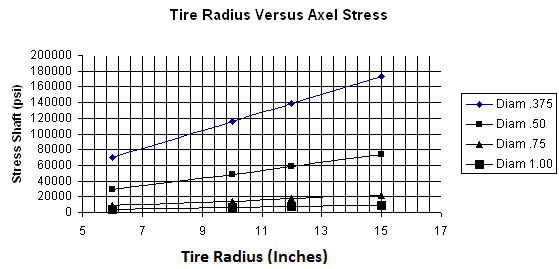

The following is a Stress Versus Tire Radius and Shaft Diameter Chart with the corresponding graph:

As the tire radius gets larger (or increase) the stress level on the shaft increases. As the diameter of the shaft gets bigger (or increases) the stress level in the shaft goes down.

The typical level of stress that is acceptable is around 20,000 to 50000 psi, depending on the type of steel that is being used. If the stress is above this range the steel will first start to bend, then break.

As you can see the bicycle wheel that has a radius of 15 inches (diameter of 30 inches) and a typical bolt size of .375 inches in diameter, will stress out at 173,840 psi. All that it would take is a good sharp corner and the bolt would snap off!

So the question then is, “How in the world can you use a bicycle wheel on a go-kart?!” The answer lies in what works.

The bugger design that we were looking at before is stronger. It is stronger on two accounts:

- Shaft diameter: .50 inches

- Wheel diameter: 7 inches

If you ever look at wheels, especially spoked wheels on Ultra Light Aircraft, Wheel Chairs, or Motor Cycle Side Cars, you will notice larger shafts, upwards to 1 inch in diameter. The primary reason is the side loading stresses that we have just investigated.

If you ever look at wheels, especially spoked wheels on Ultra Light Aircraft, Wheel Chairs, or Motor Cycle Side Cars, you will notice larger shafts, upwards to 1 inch in diameter. The primary reason is the side loading stresses that we have just investigated.

So in order to use a bicycle wheel you need to upgrade the shaft somehow, or get a smaller size wheel, maybe off of a kids bike.

The only other alternative is to mount the bike wheel in the bike frame, and have two bike frames wheeled (or fastened) together, but that kind of defeats the purpose of simplicity.

Mounting the Wheel to the Go Kart

Once you have gotten the correct size Wheel and Shaft combination, the question comes in “How do you mount the shaft to the go-cart?”

The shaft can be inserted into a tube or channel and then welded in place. See the bugger example below on fixing the shaft to a channel:

Putting Power to the Wheels

The nice thing about bicycles is that chains and sprockets already exist. The question is “How can I use the chains and sprockets effectively? Is it possible without getting too complicated?”

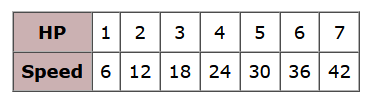

The question is related to the amount of horsepower that you have. Typically the amount of horsepower is related to the speed in the following graph:

The drive ratio for your motor to wheels is derived from this chart then.

The following calculation process is to determine the sprocket ratios required to get the gokart to perform decently.

- Wheel RPM Calculation

- Ideal Drive Gear Diameter Calculation

- Reduction Drive Calculation

So if you have a wheel size of 15 inches in diameter, and an engine of 3 horsepower the top speed will be 18 mph. {The top speed of the engine is assumed to be 5000 rpms for these calculations}.

Drive Wheel RPMS Calculation

RPM Wheel =336.135 MPH/ Wheel Diameter

RPM Wheel = (336.135* 18 MPH)/ 15 inches = 403.36 RPM

Engine Drive Gear Ratio Calculation

Now we need to determine what is required for gear ratios between the engine and the drive wheel. The simplest system is to have an engine gear and a drive gear on the wheel.

Engine Gear = EG = 1 inch diameter

Ratio = (RPM Engine/RPM Wheel) = 5000 RPMS/403 RPMS = 12.40

Drive Gear = DG = EG*Ratio = 1 inch * 12.40 inches = 12.40 inches

As you can see the resulting ratio may be a bit much. Especially in light of the fact that we were hoping to use the sprockets that came with the bike.

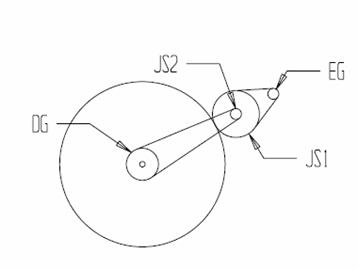

Not to worry, the next calculation helps us determine sprocket system that in combination is more compact. It is called a jack-shaft system, the principle used in transmissions on cars and tractors.

To Calculate the reduction system the following formula applies:

Final Ratio = DG/JS2 * JS1/EG

In the above design JS1 was selected as 4.125 inches, and JS2 as 1.00 inches. The formula then reduces to the following:

DG = Final Ratio * JS2 * EG / JS1

DG = 12.40 * 1.00 * 1.00 / 4.125 = 3.00 inches

If DG is already known, then the following calculation can be used:

JS1 = Final Ratio * JS2 * EG / DG

Conclusion:

In order to get make a cheap go cart out of bike parts, you need to understand a bit about strength of materials. In otherwords, will these bike parts hold up, or will they break?

Also, the amount of horsepower that you have on hand, will it make the go kart go very fast? Will the go kart even move?

These are questions that can be answered in the go kart performance calculations section by calculating the horsepower, weight and gear ratios into a go kart. The spreadsheet will then calculate the expected performance of the gokart design.