Vertical engines (where the shaft of the engine points up and down) make things complicated when it comes to transferring their power to the wheels. The engine shaft points straight up and down, and the driving axle is at 90 degrees or is horizontal. To get the power from the engine to the wheels can be a challenge. Right angle gear boxes, and interesting belt configurations can be devised.

The simple alternative to mega complicated systems is the twisted belt system. Inherent in the twisted belt drive is

- Belt Slippage

- Belt Tracking

- Belt Tensioning

If the system is set up properly it works excellent. Careful attention is required though, to proper geometrical relationships for the system to work properly.

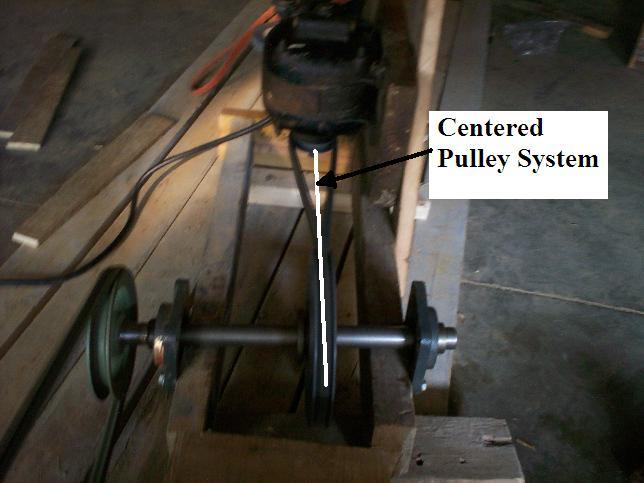

First of all the centerlines in two planes must be lined up. The purpose for the lining up is that the belt will track best this way. (The best analogy is to look at your vacuum cleaner. Look at the twisted belt relationship between the impellor and the sweep mechanism. They are line up in two planes.)

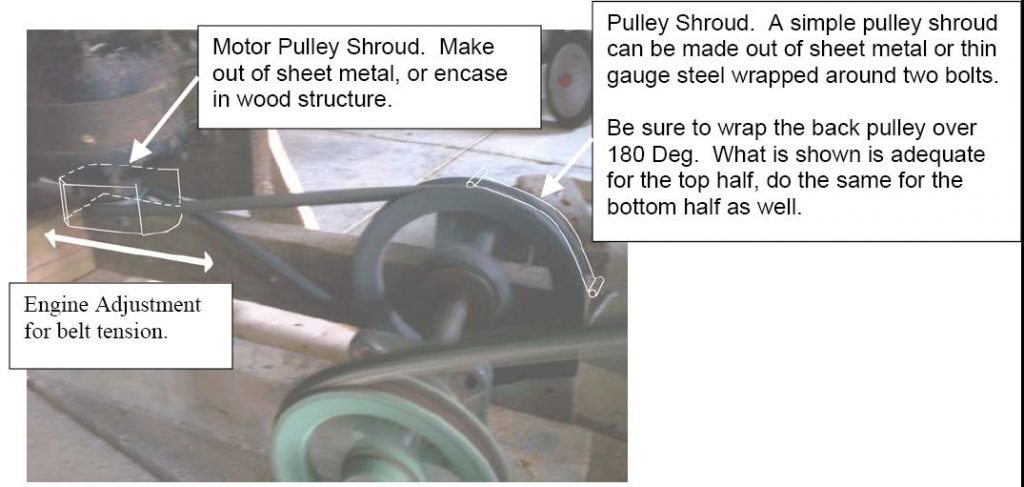

Secondly, to adjust the tension of the belt the engine can be slide back and forth to adjust tension. To keep the belt from falling off the pulleys, when the belt tension is lax, the pulleys need to be “shrouded” to keep the belts around and in the pulley tracks.