A riding lawnmower tractor is one of the best resources or goldmines for sourcing parts for a homemade go kart. There are so many goodies on the riding lawnmower that it just makes it the best bargain around for fabricating your own go kart. Typically a riding lawnmower can be had for 50 dollars because the owner just wants to be rid of it.

However, and this is a big however, there are some secrets about how to use the parts that just aren’t discussed because most don’t know what the solutions are.

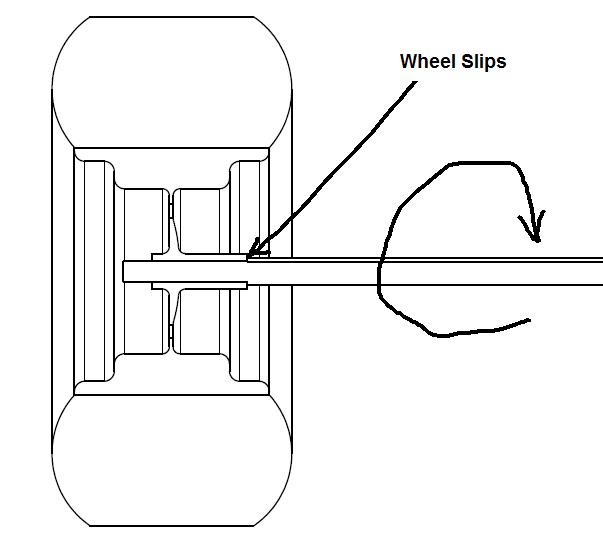

This article is about taking a riding lawnmower rear wheel and mounting it to a “live-axle” on a standard go kart. You might be inclined to just close your laptop and stop reading this article because “This is just a no-brainer right? I mean, anybody with half a brain knows you just slip the go kart axle into the hub of the riding lawnmower wheel and walla…. (viola actually)…you have an instant cheap go kart wheel.”

Uh….No. Have fun with that…

As I said this article is about mounting that rear axle to the riding lawnmower wheel, so let’s get to it.

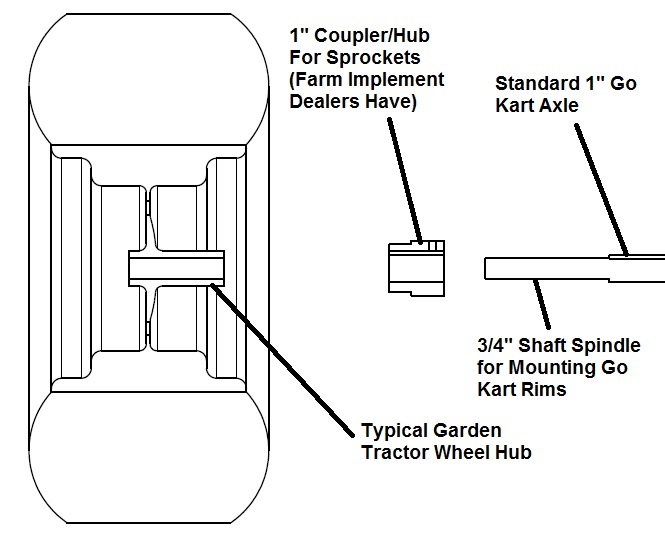

There are two types of axles on garden tractors: the splined versions and the ¾ shaft keyed versions. The lower cost riding lawnmowers invariably have the “¾ shaft keyed versions.” We will call them the TQSV (Three Quarter Shaft Versions) for short from now on. Just as an FYI, the splined versions are more difficult to use and require custom parts. That’s where 3d printer and a friend who can do casting comes in….but that for another article.

The conundrum with the TQSV hub is that it is ¾” in diameter and gokart shafts are 1 inch in diameter. There is a reason why the axles on a go kart are 1” and in some cases larger, it is because they will bend if they are any thinner. For example we have a “Will our go kart shaft bend page” on our web site that helps calculate the amount of distance from the frame a wheel can be before it will bend the axle on the go kart. A shaft will bend like a diving board if hanging out too far from the frame.

The reason I say it is a conundrum is that the wheel/hub will not fit neatly onto the go kart shaft.

The axle will just spin in the hub, because the key-way is in the one inch section of the go kart axle. The problem is how to connect the axle to the riding lawnmower wheel?

The wheel can be slipped over the threaded section of the axle, but there is nothing to make the axle and hub connected, or solid.

There are three issues with the wheel and axle assembly that the rear wheel hub will have:

1. Locking the hub to the axle in a rotation (translation: making the axle transmit power to the wheel, otherwise it will just spin.)

2. Locking the hub on to the shaft in a horizontal or along the shaft (in plain English, keeping the hub on the shaft so the wheel doesn’t fall off)

3. Removability: the wheel should be able to be removed for service.

The quick and easy solution would be to weld the rear wheel onto the axle; however that poses some very significant maintenance issues:

1. Removing the axle,

2. Placing chain on the sprockets,

3. Placing bearings on the shaft,

4. Placing the assembly into the go kart….just to name a few.

Welding the axle to the wheel hub is possible for one side, but not for the other side of the axle.

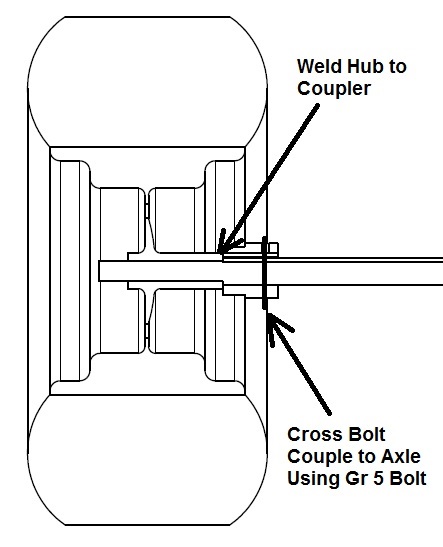

The answer lies in a weld on coupler. The coupler will provide the keyway necessary for transmitting torque to the wheel and then a cross bolt across the coupler will keep the wheel on the axle.

To accomplish this, place the coupler and the wheel onto the axle. The axle will act as a “weld fixture” holding the coupler in place. Prepare the surfaces of the hub and the coupler and then weld the hub and coupler together.

To keep the coupler from sliding off of the axle, a cross bolt will need to be drilled across the coupler. The size of ¼ -20 grade 5 or grade 8 bolt should be used (do not use grade 2!). Do not make the mistake of having the bolt transmit torque. The axle can deliver enough power to shear off the bolt, so the keyway must be used to transmit torque. The cross bolt is only designed to keep the wheel on the axle; this same concept is used on riding lawnmowers frequently.

The importance of the keyed coupler cannot be stressed enough, because this is where the power can be transmitted to the rear wheel. The shear area is much greater on a key than on a cross bolt. A cross bolt has its uses, but more for keeping nuts from turning, or for applications where side loads are minimal, such as retaining a pivot pin.

The importance of the keyed coupler cannot be stressed enough, because this is where the power can be transmitted to the rear wheel. The shear area is much greater on a key than on a cross bolt. A cross bolt has its uses, but more for keeping nuts from turning, or for applications where side loads are minimal, such as retaining a pivot pin.

So to recap, the riding lawnmower rear hub can be retained using a weld on coupler that transmits the torque through the keyway and is retained in place with a cross bolt.

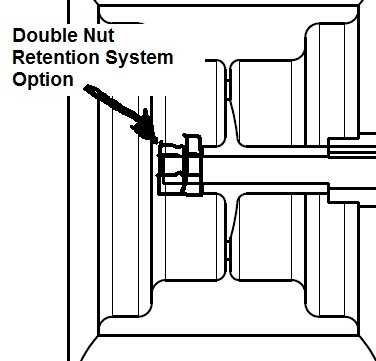

As a side note if there is enough shaft exposed outside of the hub of the riding tractor wheel, then a nut can be used. If using a nut it is essential that the nut cannot loosen. Don’t make the mistake that a large ¾” nut is not going to loosen. It will loosen, with acceleration and braking, the axle hub transmits tightening and loosening torque on the nut and it will follow Murphy’s law and loosen. To keep the nut from loosening (lock-tight WILL NOT WORK), either double nut (jamming a nut on the tightening nut), or castle nut (a special nut that has openings for a cotter pin) the axle hub mount.

As a side note if there is enough shaft exposed outside of the hub of the riding tractor wheel, then a nut can be used. If using a nut it is essential that the nut cannot loosen. Don’t make the mistake that a large ¾” nut is not going to loosen. It will loosen, with acceleration and braking, the axle hub transmits tightening and loosening torque on the nut and it will follow Murphy’s law and loosen. To keep the nut from loosening (lock-tight WILL NOT WORK), either double nut (jamming a nut on the tightening nut), or castle nut (a special nut that has openings for a cotter pin) the axle hub mount.

A double nut application to keep the wheel from falling off. A double nut acts likes jam nut that can be loosened when needed. It has superior holding power over conventional jam or nylock nuts.

Limitation of Liability Statement:

The Go Kart Guru assumes that you have a full working knowledge of mechanics, and are at least 18 years of age, or accompanied by adult supervision to aid in the project development.

Under no circumstances, including, but not limited to negligence, shall the Go Kart Guru (Gamble Industries LLC) or its affiliates be liable for any direct, indirect, incidental, special or consequential damages that result from the use of, or the inability to use, materials presented here. You specifically acknowledge and agree that the Go Kart Guru is not liable for any improper, welding, material selection, tubing selection, mechanical layouts suggested in any correspondence whether emails, or materials such as plans or web site materials.

Nice detailed article on this option for go karts’ wheels. Innovative approach.