Sometimes I have to shake my head when different drive systems are proposed. I shake my head because a drive system is designed to transfer the drive torque of the engine to the wheels, yes that is true, but how much torque is the clincher.

Very often we think that just routing a system together and getting the two to join in rotation is sufficient. In a large number of cases, it isn’t just a slap and go system.

The reason is that the engine output must be matched to the rear wheels with the correct overall output ratio. If not the engine will do the following:

1. Smoke the clutch

2. Smoke a belt

3. Stall the engine

4. Won’t Climb Hills

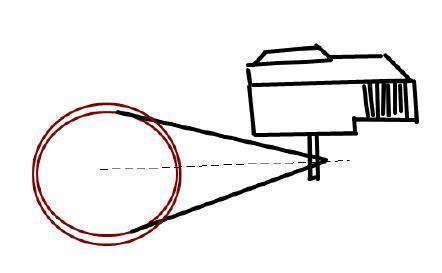

If you recall from some previous articles, the rule of thumb for sprocket or belt drive sizing is that the size of the sprocket or pulley for the driven section must be at least 85% of the diameter of the wheel size. Secondly, the drive sprocket on the engine must be at least 10 to 12 teeth (or in the case of the pulley) 1 ¾ diameter at a max. This rule of thumb will give you the needed ratio for good overall performance.

Unfortunately with a vertical drive engine, using a twisted belt requires a couple of things:

– Center Line-Pulley Line Up

– Sufficient Space Or CC distance between Engine Shaft and the Final Drive

Twisted Belt Drive requires the proper ratios in order to not burn up belts. This particular design is very susceptible to burning belts, on the smaller pulley.

What this often requires is that the engine be dropped so that the pulley is in line with the rear axel. Additionally, the engine needs to be brought back or in front of the axel a large distance (12 to 20 inches in some cases).

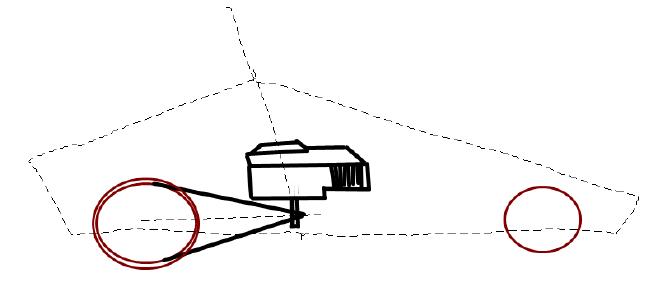

Twisted belt drive crowding the person compartment on the go kart. The engine needs to be brought forward to give the correct space required for the belt to track. The go kart would have to be lengthened to make this scenario to work, causing the go kart to get heavy and the center of gravity to be to far forward.

This presents a problem because on two accounts, it either eats up valuable real-estate and crowds the drive, making a long and unwieldy go kart, or it puts the engine back too far on the go kart causing it to have very poor CG placement which redounds to very poor steering performance.

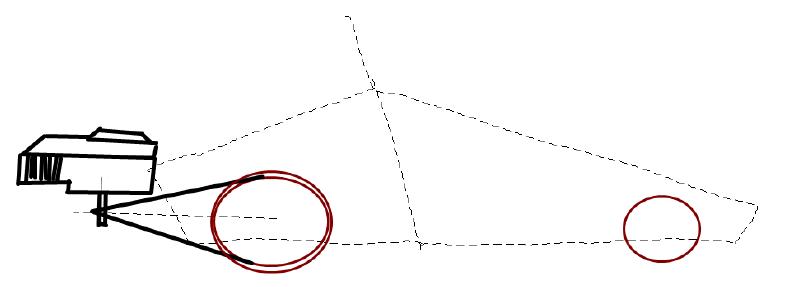

Twisted belt drive placed too far back on the go kart. This particular design has the engine placed way behind the drive wheels. This makes the center of gravity too far back on the frame, causing the wieght to be too light over the front wheels. This will cause the CG to be too far back and will caus the go kart to pop wheelies or not be able to turn well. Often this design is suggested on wood go karts, which is a poor design choice.

In case you think I am against twisted belt drives, I am not, what I am against is a twisted belt drive that doesn’t perform, that is ill-designed, or not matched well to the go kart. A properly designed twisted belt drive will work just fine, if the ratios are set up correctly.

Getting the set up so that it fits into a go kart and does not cause other problems, like CG placement, steering problems (insufficient weight on the front wheels), tracking problems, clutch engagement problems and so on….that can be a very large challenge to get all those ducks in a row.

The twisted belt drive is a viable system, it just depends on how you set it up.

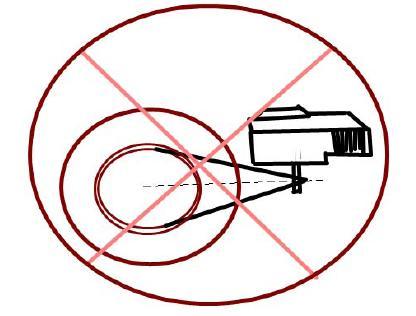

This particular belt drive set up will not work, because the size of the wheel is too big in relation to the driven pulley. The overall ratio is insufficient for the go kart to get going, with out stalling. Additionally, this system will burn through belts terribly and the go kart will have trouble even starting from a stop, not to mention not being able to climb any sort of hill.

For more information on vertical engine drives visit the Go Kart Building 202 series.

I’m using the twisted belt drive system, and need a bit of advice. My drive pulley is 1.75 inches in diameter. My rear tires are 11 inches in diameter. How big of driven pully should I get? Thanks

As a rule of thumb the rear drive pulley should be around the size of the tire, or 11 inches in diameter. This rule of thumb is based on a typical wieghted gokart. All bets are off if the go kart weight is something ridiculous. The best thing to do is get the proper ratios deterimined by using the drive calculations program found here.

Typically an accelleration of around 1/4 g is acceptable on a go kart. You may discover that the ratio of the 11/1.75 is insufficient for your go kart because it is too heavy and underpowered.

We go into alot of the specific details in our 201 book found here: Go Kart Building 201: Black Box With Gears, Sprockets….

I found some smaller rear wheels. About 6 inches. Would a 3.75 inch driven pulley be too small?

The main problem that you are going to run into is that the overall ratio really needs to be addressed. If you put all the perinent information such as:

Wieght (includes person) of the go kart

Engine Horsepower

Engine Driver Diameter

Rear Wheel Driver Diameter

into the program found at https://gokartguru.com/go-kart-engineering-tool-kit/ The output result will tell you what to expect from the go kart by way of performance.

If it takes more than 8-10 seconds to accelerate in the 200 foot span, then the ratio is in question, meaning it is not steep enough and the engine will stall, clutches will burn.

Could I just pick up an old right angle gearbox instead?

Right angle gearboxes are alright, but be careful what you are selecting. The reason why I say that is that Gearboxes are hp-rated. You can overheat, and burn up the gear box if it is not at the proper rating. If that is okay with you, then it should last for little while until it breaks.

As far as finding a right angle gear box that can be a tall order and quite costly. So I recommend using our system found in the 202 book. It is much, much cheaper, easier to diagnose and repair (if ever needed) and works with a wide range of horsepowers.