On gasoline engines the primary method for causing the fuel air mixture to become ignited is to use a spark. The spark is generated using high-voltage electricity which jumps across a gap in the engine combustion chamber. We all understand this process that the spark plug must give spark and therefore the engine will run properly, however we don’t generally understand how the spark is generated and what the mechanism is that causes this whole event to occur.

In this particular discussion we will talk about magnetos and solid state ignition systems, additionally we will talk about old-fashioned car coil systems because often times larger two cylinder engines will use a coil which operates off the battery.

Understanding ignition systems is that you are trying to manage high-voltage electricity. As we all well know when you put your hand on a high-voltage fence (such as an electric fence to hold cows in the pasture) is a very large hair-raising experience which is very unpleasant.

Trouble is when you’re trying to manage or regulate high-voltage electricity it can do some damaging effects to electronics and circuitry. So the better method is to use secondary systems that don’t need or have wear components to them that would be affected by the high-voltage electricity.

The best way to manage the high-voltage electricity is though magnetic fields because magnetic fields don’t have mechanical parts to them. They are, if you will, unseen forces that can hold caustic and dangerous environments at bay.

For example magnetic fields are used to constrain high temperature plasma gas such as is used in a fusion reactor. Man-made magnetic fields are used to contain the fusion gas and therefore protect the mechanical containers from becoming destroyed.

The same concept is being employed when managing high-voltage electricity but out of smaller, more cost-effective and downsized package. The magnetic field is being used to work with high-voltage spark plug of electricity.

To analyze the ignition system for a small engine we are going to start with the earliest design which was the magneto points system.

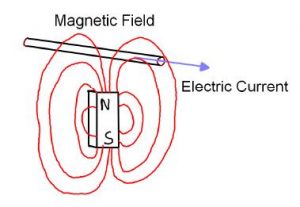

Magnetic Field Passing Through a Wire Causes an Electric Current: Faradays Law

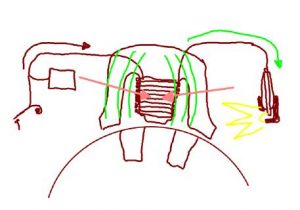

The magneto points system consists of a flywheel with the magnet in it, a magneto, and a points system.

Basic magnetic theory is that when a magnetic field passes by an electrical wire it induces an electric current in the wire. This basic concept is used to generate electricity in power plants. A magnet is passed by electric wires and electric current comes out of these wires and is used to light bulbs in your homes. That is the down and dirty simple explanation of how electricity generated.

The concept is that when a magnetic field is passed by a wire it generates electricity.

A similar concept is used in generating magnetic fields. When a coil of wire is wrapped around an iron core and electricity is introduced into the wire a magnetic field is generated.

Now you can do a combination of making a magnetic field using electricity and taking a magnetic field that was just generated and causing electricity to be generated by the magnetic field that was just generated.

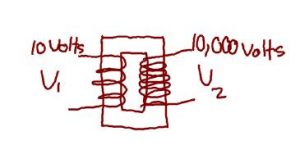

Transformer Takes Input A/C Electricity and Converts it to a Higher Voltage, but lower current

That sounds like a perpetual motion machine. Actually it’s not a perpetual motion machine is more like a open tube. Water will flow fine through the tube, but when you restrict tube the flow out of the tube will be less and the pressure may be higher.

What were are talking about is the concept of a transformer where electricity is generated on one side and stepped up or down on the other side of the transformer. The requirement however for the transformer to actually work is that the magnetic field is constantly being created and destroyed. The destruction meaning the collapsing of the magnetic field is where the electricity is generated.

The magnetic field in other words is falling back from where it started from and during this falling back phase it falls through wires and can generate electricity. The generating of electricity is based Faradays’s law of magnetic fields.

So a magneto is a glorified transformer that is turned on and off at certain times so that high-voltage electricity can be shoved through the spark plug. The turning on and off of the transformer is accomplished by the points.

The points on the left close, causing the field to collaspe (pink arrows). The collasping field generates a spike which transfers into the spark plug coil. Spark plug on the right.

The magnetic field for the first wire, which is called the secondary wire in a magneto is generated when the magnet on the flywheel passes by it. The points suddenly opened causing the magnetic field to collapse because the circuit is shut off. The collapsing magnetic field passes through the windings inside the primary coil winding causing a large spike in the electrical voltage. This sudden spike in electrical voltage is called a spark as we see in a spark plug.

There certain parts of the magneto system that are designed to absorb electricity so that they are not worn out during the whole process of switching. The device that were talking about is called a capacitor. The capacitor takes the electricity that would like to jump across the points gap and absorbs it or cushions it in the condenser or capacitor.

A capacitor is kind of like a spring. It absorbs the energy of the electricity and prevents it from actually jumping across the point gap. The reason for this is that the points will become pitted and soon become dysfunctional or non-operational if the condenser or capacitor is not in the circuit or working properly.

Coil Systems

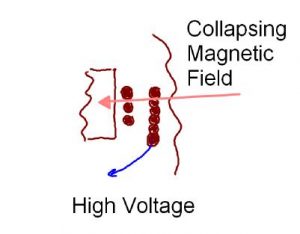

Coil Operation: The inner coil (3 wires shown) is turned off. The magnetic field collapses through the outer primary coil. As the field collaspes it generates a current of high voltage spike in the outer primary coil.

On a car a coil is used to act as a high-voltage switching device. Up till about the late 80s and early 90s coils were used extensively to supply high-voltage current to distributor caps even though points were not being used in the system. The switching was accomplished using solid-state circuitry, however that basic concept of switching a coil “on” and “off” was still maintained.

What occurs with the coil is that the coil is activated and deactivated using a switching device. The coil consists of two sets of coil wires. One set of coil wires is wrapped first on the iron core. The second coil of wire is wrapped around the first coil wire system.

The first wire has 12 V of electricity that is induced into the circuit. When the electricity is turned off to the coil a magnetic field correspondingly collapses back into the first coil wire system. This collapsing magnetic field passes through the second set of windings causing a large high-voltage electrical current to pass through it. This high-voltage electrical current is used to cause a spark in the spark plug.

The means to cause the coil to turn on or off a points system or a solid-state circuitry device is used.

Solid-State Magneto System

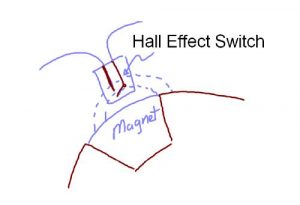

The solid-state magneto system uses electronics to do the switching. Typically the electronics uses a magnetic field again, to activate a Hall effect sensor which does the switching.

When the magentic field passes by the Hall effect switch, it automatically turns off the switch.

So when a magnetic field passes by from the magnet on the flywheel and Hall effect sensor (a switch that is activated by magnetic fields) collapses the secondary field, or causes the circuit to be opened up and stop functioning. Remember when the secondary circuit is open up, the magnetic field collapses because electricity is being pushed through it anymore the electricity must return from where it came or collapse the magnetic field.

On a car the same principle is used to generate high voltage sparks. The solid-state switching is accomplished using computers and Hall effect sensors mounted on the engine block close to the main belt drive system.

The nice thing about solid-state systems is that their compact and they don’t require mechanical linkages such as fly wheel weights, vacuum lines and other complications.

Troubleshooting Ignition Systems

The question comes in when you’re troubleshooting these electronic systems how do you know what the problems are?

Well the troubles occur in the following three areas regardless of whether or not it is a solid-state ignition system or not:

1. Ignition coil

2. Switching

3. Main power

The ignition coil is the device that switches magnetically to high-voltage using an on off the circuit. The switching device is what turns on and off the coil. The coil must first be excited or full of electricity before it can be collapsed. So an electrical current is required to be generated first in to the coil.

In a small engine the electricity is generated using the magnet of the flywheel. The magnet obviously must exist on the flywheel. If there is no magnet there is no electricity being generated.

The first thing to examine is whether or not there’s a magnet in the flywheel. In other words is a magnet dead or not? To test this put a screwdriver or a piece of metal on the flywheel magnet and if it holds it in place then the magnet is fully charged.

The second thing to examine is whether or not the points system is working properly or not. This requires inspection of the points system. If the points are painted they need to be scraped and cleaned. This will keep at bay the problem of nonfunctioning ignition system, however it is indicative of a points system that needs to be replaced and most especially a capacitor that is faulty.

On a small engine that does not have points if you’re not getting spark when the magnetic field passes by from the flywheel then the solid-state ignition is faulty. There is one exception to that rule however and that is the way he a solid-state ignition system is turned off. The solid state ignition is turned off when the wire coming out of the solid-state ignition system is grounded. What this does is when you take the circuit, (even though it is internally solid-state )and ground it to the framework of the engine the circuitry fails to function properly and the magnetic field is not collapsing anymore therefore no more spark is being generated.

So if the grounding wire is off of the framework, or is not shorting onto the frame of the engine, then the solid-state ignition system should be working properly and you should get spark. If at this point in time you are not getting spark than the solid-state ignition system is faulty.

(Note: a way to destroy a solid-state ignition system is to induce electric fields into the grounding wire. The solid-state ignition system is not designed to take high-voltage electricity or any electricity for that matter and back-feed it into the grounding wire. A common problem that occurs with solid-state ignition systems is that the alternator wire is accidentally hooked on to the grounding wire. What this does is that it induces an electrical current into the solid-state module and burns out the Hall effect sensor circuitry. So beware of putting any sort of current onto the solid-state wire system.)

Coil System Trouble Shooting

On a larger engine that uses a coil system the general principles basically simple. An electrical current is being generated by inducing a voltage through the secondary circuit. When this secondary circuit is turned off the magnetic field collapses through the primary wire and causes a high-voltage to come off the center of the coil. So if the system is not working it typically is not the coil’s fault, it typically is the switching device that is at fault.

Care must be taken to make sure that the solid-state ignition system which is turning the coil on off has the correct wire coming off of it. All that is required for this system is electricity is turned on to the solid-state ignition module and electricity then flows from the module to the coil. The module acts as a switch turning on off. The way the module turns on and off users typically a magnetic field off of the engine flywheel.

From a packaging standpoint the coil switch is a simple device bolted near the flywheel magnet interface.

Bottom line is that an ignition system is trying to manage high-voltage by switching using low-voltage. The complication comes when you’re trying to turn on and off the low-voltage circuitry. This can be accomplished using a mechanism such as points, or a Hall effect sensor such as a magneto uses, or a computer as is used in a car.

I have a 2 cylinder ONAN engine that keeps having capacitor failures. I put a new one on and it runs for about 1/2 hour and stops. What causes a capacitor to go bad?

Mike,

Capacitor failures can come from not having the points set up properly. How do you know you have a capacitor failure? That is the big question. Typically the system will still work, but you will get a big spark across the points. The big spark across the points means that the electricity is just jumping direct across the point gap versus the spark gap. Is this occurring or is the engine just not running right?

We have an old victor engine go kart that we can not get a spark from the plug. We suspect that the points are not working or wired incorrectly There is no magneto, just a battery.

Bottom line on an engine you need to have HIGH VOLTAGE and the only technology that is available for getting high voltage is through a coil.

Look for a coil type unit on your engine. It may have been removed. Also, this engine may have required a battery to excite the coil, that is why it has points, no coil and perhaps battery connections.

The coil is “pumped up” to the full capacity, then the unit is shorted so that the magnetic waves fall back through the inner coil causing a spike. This principle is used on all ignition systems, even the ones on sophisticated cars.

I have a yamaha kt100 kart engine on an ultralight plane . I changed it over from a points system to a tci system with a new coil and new tci module, I get a low voltage spark through the spark plug wire but not enough to fire the spark plug .The tci module is mounted and grounded to the motor. There are two wires comming out of the coil besides the spark plug wire one is a green ground wire the other is a black wire with a “y” on it going to the tci module , should this wire have voltage coming from the coil to the tci module ? Thanks for any help, Rich

Bottom line is the coil is not getting up to full strength. The object again of the coil is to get it fully to have the primary winding excited. When tje coil is shorted, the magnetic flux lines collapse causing the high voltage spike, which you see as a spark. You can test the coil by removing it from the unit, charging it up and then shorting the coil. You should see a hefty spark. If not…the coil may be compromised.

All the TCI module is doing is inducing voltage, and killing it, or exciting the coil and then shorting it using solid state circuitry. The solid state part eliminates the points and the condensor system so that there are no working parts to wear out.

You are right, grounding it is important. I can’t help you much else, unless I see a wiring schematic of the system we are talking about.

Regards

GKG

How do you go about charging a coil? Also this engine is on an old easy riser ultralight airplane all I have to start it with is the prop do you think maybe i’m not spinning the prop fast enough to generate spark? or does it matter how fast the magnets spin pass the magneto? The coil and tci module are new out of the box bought from comet racing , a reputible company I am sure but no spark, just trying to eliminate human error on my part. Thanks for your help !

hello again guru, my yamaha kt100 kart engine has a magnito type ignition with the magnets in the flywheel instead of points it has a tci box or module.i talked to a 2 cycle mechanic at comet racing where i purchased the new magnito {coil} and tci module and told him the same story i told you about no spark i also told him i was changing it over from a points system to a tci system, he said the kt100 never had a points system and gave me the number to a rep from yamaha motors U.S.A. and he said the same thing he also said if whoever put the points on the engine could have changed the flywheel and it could be too week to support the electronic ignition or the magnets could be in the wrong position or the timing could be wrong for the tci ignition .so what i am asking is since i changed over to the tci ignition should i change the flywheel also ?i hate to keep bugging you but you seem to know what you are talking about and wouldnt profit from me buying an $88.00 flywheel . thanks for any help you could give me

It is amazing to me how things turn into Sherlock Holmes when you are just trying just to get something to run. Seems that I would agree with the mechanics. If somebody changed the flywheel, it could be the magnets are too week as they said, or they got damaged over time. Dropping a magnet can weeken its strength, so can scratching stuff accross it. So it they is an interference when the engine is running, you can actually damage the magnet. I would get all factory parts on the engine, that way you know it is designed to run, and will probably run.

I have had to stare myself in the face after working hours on a project and break down and just get the right part. In this case it is one of those projects.

You may want to consider a new motor, seeing the flywheel is 88 bucks, you may want to consider a different motor for the same price or less off of e-bay or craigs list.

Hey guru ,Sherlock here again, I have three magnets on the flywheel of my 2 cycle yamaha 1 magnet at 12 o’clock 1 at 5 o’clock and 1 at 7 o’clock that makes three magnets, I learned that at elementary school Watson, the 2 bottom magnets are pretty strong still but the one at 12 o’clock has nothing at all.Case solved eh, guru? Thanks for all the help, and my apollogies to Sir Arthur Connan Doyle .

My ’78 straight shaft YAMAHA KT100 Kart engine ,does it make a difference which way the flywheel is installed? Mine is backwards to make it counter clockwise it also has two diffrent slots in it for the key way like its made to be reversable . The new one i ordered is for a newer engine and fits a tapered shaft and will go on only one way….[imagine that] I also noticed that 2 magnets are strong and one is week the same as my old one, so does that mean my old flywheel is still good ?and do you think it is reversable? Thanks

Hi-running a 2-stroke kart with ignition problem. It sparks once when I first hit the start button (it’s electric start) but then rarely does is spark unless I release start button and then press again, sometimes I get a weaker spark but only occasionally. Any ideas-could this be the coil?

Hi GKG, great articles on Magneto and Ignition, could you tell me the optimum air gap between the coil and flywheel. I have been told 0.4 to 0.5 mm. The engine is a KT100 running TCI with NGK Iridium plug

Thanks

Mike

Mike, your gap of around .015 to .020 sounds right. I typically use a credit card thickness, or use a paper bag thickness between the magneto and flywheel. The strengh of the magnet is the square of the distance, so theoretically the closer you get the stronger the magnetetic field transfer, but there are mechanical limits such as bearing slop on the crank and so forth which limit how close you can get. .015 is pretty close anyway!

Thanks for the comments!

I have 1969 west bend 820 engine that I would like to convert from point system to electronic ignition. I bought a pvl modual PN Art.NR. 455140 made in Germany. I applied to the motor, but had no spark, with the spark plug removed from the engine and grounded I spun the flywheen in the normal direction of rotation (no spark) I then reversed the rotation and had spark. This tells me that the polarity of the magnets in the flywheel has the wrong polarity. I can’t find anyone so far that can reverse the polarity.

Can you turn the module around 180 degrees, in other words mount the pick up module in reverse? Can you adapt the pick up module so it could be mounted in reverse? This would do the same thing.

It’s not possible to change the position of the module or at least not without a major modification. I’ve learned that the magnet’s polarity can’t be changed, because of there physical properties and I can’t contact the manufacture of the module to see if they make a module with the opposite internal switching. There email address is rejected. info@pvl-ignitions.com

http://www.kernrokon.com/1969_rokon_points_to_pvl.html

Here’s a link to a vidio that I made.

You are right, nigh to impossible to flip the module around. The only thing I could think of was remagnetizing the magnets so the poles flipped. But that requires a very strong magnet, and or heating the magnets and then striking them when the temp drops. Unfortunately the temp required probably would melt the flywheel.

I am suprised the manufacturer doesnt make units that are designed for the other direction, because not all two cylces go the same rotational direction.

To my knowledge these flyweels are no longer in production and I believe that they did make some flywheels with the polarity reversed, but they are very difficult to come by. I guess for the time being I will have to use the point system. Thanks for your help

Dear Guru,

I have a baja dn150cc that is not getting any spark to the spark plug. I checked all the wiring and I replaced the ignition coil wire. Should I replace the magneto coil? If I have to replace this peace how do I get to it? Would I need a pully puller to remove a metal hub around the magneto coil? Please Help. Thanks Michael

Depending on the vintage of the engine, I am guessing it is a solid state system. In otherwords, if the vintage year is within at least 1995 and later, the engine has a magneto system. That being said there has to be a way to STOP the spark when it is running normally. Look at the wires coming out of the magneto. There really should only be one and that is the grounding wire. Make sure that wire is not touching the ground and then check your spark.

You may be having trouble looking at this magneto and I am guessing it is because it is stuck underneath the flywheel. Tis a shame to have to pull the flywheel just to find out that the grounding switch is faulty. IF the flywheel does have to be removed, that can be a tricky affair. To remove it use a puller, but be careful to make sure all things are lose when doing so. Try not to hit the hub or flywheel with a hammer, as this can cause instant death to the magnets in the flywheel and also can crack the flywheel.

If the wires are checked and the engine “suddenly quit” then the magneto is probably the culprit. Be prepared to pay for the magneto it will run in the 80 to 100 dollar range.

Go KartGuru.com

I have a yamaha kt100 with a new coil and tci out of the box …no spark…is it true you have to use a pull crank or an external starter to get the motor spinning fast enough to get the spark to jump ? turning it over by hand doesnt seem to do it.

Theoretically yes. What is needed is a switch to turn the coil system on and off. Typically the solid state system use a switching device, such as a distributor, or even a magnetic pickup that connects through a micro computer that outputs the signal needed for the Ignition coil pack to be activated.

Obviously be careful, you need to know how the unit is switched first, or you will end up frying delicate components.

On a car for example a coil system is feeding the distributor the high voltage power. The coil itself however has a “brain” that switches the mini coil inside it on and off. This solid state system does not need “points” or a capacitor, because the energy is absorbed internally in the “brain board.”

The coil itself however is fed from the “main brain” that fires off signals to turn the secondary switching coil on and off. You may have success if you can figuire out what kind of voltage is being fed into the main coil driver. Typically an oscilliscope is needed to access what the “car style coil” is actually doing.

You may want to consult some ignition coil manufacturers and see what is required to hook up a solid state system to a simple engine with a single magnetic pick up.

I used the stock coil as a magnetic pickup since the stock coil output is 12v