The wood go kart steering is based off a bogie mechanism where the front wheels are mounted to one axle and the main axle on the front pivots at a center point. The bogie concept is based on basically a wagon geometry however it is very efficient as far as vehicle dynamics are concerned, because it has a true arc path.

In order for the bogie system to maintain stability it must be constrained in the z-axis. What I mean by the z-axis is that the up and down motions of the axle system are not allowed to move. The side to side motions the x-y motions are allowed however the up and down motions are not allowed.

The reason for the constraint of the axle system is to keep it from suddenly jumping up in the air and causing an imbalance situation.

The main constraint with a bogie system is trying to get it to connect to the steering mechanism, such as a steering wheel. The basic way to make a bogie system move is through a cable system, where the steering wheel is turned and the cables are pulled in and retracted on one side and extended on the other side.

The rule of thumb is that when the steering system is set up, the ropes are wrapping when the steering wheel is turned to the left. The left bogie is pulling in in other words and so the steering drum is rotating counterclockwise and is pulling the rope in from the left side. The right side is correspondingly extending the same amount of rope that the left side is.

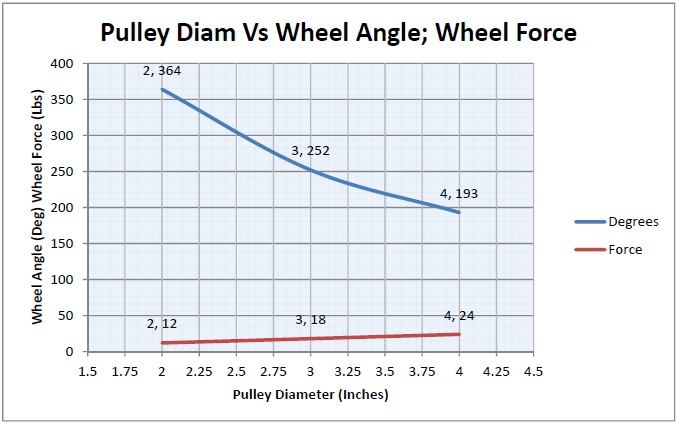

Angle of Steering Wheel Vs Angle of Bogie System. This graph is important for choosing the diamter of the pulley diameter for the main steering system. Additionally, it gives you an idea of how much steering resistance to expect. As you can see the bogie system has this main issue when designing a wood go kart.

The relationship between the steering pulley diameter and the amount of steering wheel rotation is shown in the following graph. When you have a 2 inch diameter drum it takes approximately one full turn to get the full angling of the steering bogie system. This angling is approximately 26° to 30°. To get a 180° wrap or turn on the steering wheel the steering drum needs to be around 4 inches in diameter.

The downside to making the drum larger is that the forces double. So that at a 2 inch diameter drum the amount of force required to move one side of the steering wheel is 12 pounds. When the steering drum is increased to 4 inches the amount of force required to move the steering wheel is approximately 20 pounds or more.

If a larger steering drum is desired to restrict the steering wheel movement then friction reducing materials are required to make the bogie system not bind up.

In order to make the bogie system not bind the bogie can be lubricated with grease on the bottom rails of the frame. This will allow the bogies to slide back and forth with greased surface. If for whatever reason the grease is not working out as well as it could, the bottom frame rails can be coated with either a plastic material such as a polyethylene strip, or a stainless steel plate, or a copper sheet, or a galvanized piece of steel sheeting. It is important not to have any fasteners in the sliding surface areas otherwise the fasteners will catch and bind up the steering mechanism, more specifically the bogie mechanism will get bound up.

The bogie system itself needs to be coated with plastic or a steel material as well to reduce the friction between the two surfaces. Grease should still be used regardless of whether or not you use steel or plastic so that the surfaces will slide easily.

Use of steel cables is appropriate, however, roller surfaces will be required to make the cables not bind up or cut through the wood frame work. Ropes can be used however a very strong expensive nylon style rope is recommended so that the rubbing action does not deteriorate the rope quickly.

It is recommended that the ropes be replaced every year.

Additionally the rope should be greased on every rubbing surface to make sure that the friction is reduced.

A rule of thumb about friction is that if any of these mechanisms are making noise such as squeaking noises then the surfaces should be greased so that the noises go away. Additionally the amount of force should be noticeably reduced when the surfaces are greased.

Tightening The Ropes

Tightening the ropes is accomplished by tensioning one side with a wrench. What essentially occurs is that the retention bolt becomes a mini tensioner device. The rope will be wrapped as the bolt is twisted. The compressive action of the bolt against the tube-washers will cause the rope to become blocked or bound in a tight position.

To tighten the ropes the steering mechanism is turned full to one side. Then the other side is tightened with the ratchet bolt mechanism until the slop in the mechanism is gone.

The actual diagrams for the rope layouts and the steering assembly are provided in the Wood Go Kart Building Series; and is explained in further details in the Wood Go Kart Video.