Go Kart Guru Review 2025

Over the past several years there have been some serious growing pains in the Go Kart Guru family of products.

been some serious growing pains in the Go Kart Guru family of products.

Our main core business for the longest time was the Go Kart Building 202 course with the vertical engine drive system. This rock solid system, proven with the double wide Phi Alpha 10 go kart style and a 10 hp Tecumseh engine, has been a fantastic runner. It has been dependable for go kart parties and many solo trips around the countryside. Thanks to the UTV rules in our area, we can do ample systems testing and endurance runs.

However, as I was basically trying to say, our vertical engine drive course was our main product until we shifted when another market popped up, that being the Model T Go Karts. Many owners were contacting me about getting parts to fix these go karts, as there were few and far between suppliers of the unique and costly parts.

We made the leap into helping people by first buying a Model T Go Kart and then applying parts and systems as we saw fit for the customer need. We have assembled a nice line of products that range from fenders, hubs, hub caps, radiator caps, radiator decals, aluminum wheels, to a radically improved brake system. It has been a long haul and not very lucrative, but very rewarding, as I routinely speak one on one with customers about their go karts and what can be done to help them out.

We made the leap into helping people by first buying a Model T Go Kart and then applying parts and systems as we saw fit for the customer need. We have assembled a nice line of products that range from fenders, hubs, hub caps, radiator caps, radiator decals, aluminum wheels, to a radically improved brake system. It has been a long haul and not very lucrative, but very rewarding, as I routinely speak one on one with customers about their go karts and what can be done to help them out.

The past year has been a year to remember, as it was filled full of challenges and good solutions.

Side Note

This past year brought its share of challenges. After 25 years as a successful engineer at a local company, I found myself transitioning out of that role. While there was a severance package, it naturally has limits, and the change required some adjustment. I share this not for sympathy, but to give context to what has gone into developing these products.

At heart, I am a local business owner who chooses to invest, learn, and help where I can. That is what drives Go Kart Guru. The goal has never been to maximize profit, but to reinvest in better products, better solutions, and better support for the people who rely on them. Reinvestment is not always easy, but it is central to how we operate.

Losing my job meant the cards were stacked a little differently this year, and other challenges followed close behind. At the same time, it opened the door to focus more deeply on exploration, research, and product development, which is where I do my best work.

Rather than viewing setbacks as failures, I was able to treat them as opportunities to learn and improve, even the loss of a job. In many ways, that transition pushed me to grow, stretch, and lean further into leadership and mentoring, areas where I feel I can make the greatest impact.

With that context in mind, let us dive into the year and walk through what happened.

Old Foundry Retired

Our main foundry for casting our wheels was closing their doors. Becker Precision Castings had been a great partner, working with me hand in hand to develop tooling and take a leap of faith to make our wheels. They did an excellent job for three years until they had to close due to health issues and retirement. I seriously considered purchasing the business, but the risks, especially with me not having a job, were far too great. It would have been a sinking proposition for at least ten years and probably would have taken my life with it.

Our main foundry for casting our wheels was closing their doors. Becker Precision Castings had been a great partner, working with me hand in hand to develop tooling and take a leap of faith to make our wheels. They did an excellent job for three years until they had to close due to health issues and retirement. I seriously considered purchasing the business, but the risks, especially with me not having a job, were far too great. It would have been a sinking proposition for at least ten years and probably would have taken my life with it.

That being said, I ordered a large batch of wheels, hoping they would carry me until I could come up with another solution. What that solution was going to be was up in the air, as sand casting can be quite labor and material intensive.

Attempt at Casting the Wheels Ourselves Full Time

In desperation, we contacted other foundries to see what the costs would be. We even sent our molds to a foundry in Appleton and let them try using our molds. They came back with a four hundred dollar price per wheel. It was apparent they did not want the work, and it would have been nice if they had just said no, we are not interested.

You would think in this day and age, with jobs disappearing, people would understand the little guy just trying to make a go of things. That is what is missing in the market today. The little guy is misunderstood and often looked down upon as wasting everyone’s time. A simple respectful no is all that is needed to let the little guy go elsewhere.

I think a shift in market thinking will come, with service and helping one another being the cornerstone of what business is all about. Unfortunately, the cold “its just business” attitude is permeating much of the business world and disenchanting many people in their work ethic and overall goals.

This is one nugget of wisdom I reached. Now that I have that nugget, my question to myself is how can I help people on their journey with this nugget. That is why I am writing this article.

The nugget is this: the business world is cold. Do not let it get you down. Understand the risks of investment, and understand that people have the right to say no. Accept that and move on. Costs may be too high, and that may be their business model. Do not push people to invest in you if their business model is not designed to truly help you in the long run.

Failure comes in different forms, sometimes is surprises you….like this mismatched wheel cast. Looks pretty impressive, who knows if it will take off! |

That is the lesson I learned with the foundry. The owner had a good heart. He loved me as a person and invested in me as a business because he wanted me to succeed. Those are the partnerships you want. Businesses that will not drop you because they decide the risk is not worth it.

The second nugget is to understand the risk they are taking, respect it, and constantly monitor that relationship, nurturing it if necessary so it does not disappear.

As the proverb says, “A good name is worth more than rubies and gold.” Make sure your reputation is not a lie. Constantly push yourself to do better and invest in your calling so you can help people better. Be a better speaker. Be a better communicator. Always be introspective and consider the other side as valid and having worthwhile points. Look at the problem through their eyes and solve it from there. This applies to vendor relationships as well. What pain is it causing them, and what can you do to make it easier and more enjoyable for them to work with you.

Die Cast Wheel Development

The next foray into making wheels came from rolling up my sleeves and figuring out the best solution for the customer. This required investment in die cast molding technology and complicated long run CNC projects.

The next foray into making wheels came from rolling up my sleeves and figuring out the best solution for the customer. This required investment in die cast molding technology and complicated long run CNC projects.

The idea was simple. Make a die cast mold for wheels. The surface finish should be phenomenal and the process fairly simple. It seemed like a win win situation. Make a die, pour the aluminum, and out come the parts. That was not the case.

Every technology has hidden secrets. Once they are figured out, it is like riding a bike. Die casting has its own hidden traps, literally gas traps, that can ruin parts. A fantastic die will still yield garbage parts if gas is not properly managed and a production worthy solution is not built into the die.

The mold yielded fantastic finished parts on one side only until it became clear that gas displacement was the issue. Gas forms voids much like air bubbles in a soda bottle. The gas must be removed so aluminum can take its place, and that is where venting becomes critical.

After several casting cycles and mold modifications, extensive venting was added. Once that was solved, the gas voids essentially disappeared.

After several casting cycles and mold modifications, extensive venting was added. Once that was solved, the gas voids essentially disappeared.

Cores presented another challenge. While I was doing reasonably well, I did not fully understand the core business and ended up buying a core ring that I probably could have made myself in the long run.

Because cores were such a challenge, I developed a collapsible solid core that could be released after casting. This again required venting to solve gas issues, but ultimately worked.

The real issue became through-put and equipment. After spending an entire hot summer day casting five wheels and only getting one good wheel, it was clear something was wrong. The tools needed to be preheated, timing had to be perfect, and the entire process became exhausting.

Compared to sand casting, where four perfect parts could be cast and machined before lunch, die casting proved inefficient at this scale. Better equipment would help, but the barriers to entry shut the project down. While it was a failure, many valuable lessons were learned about machining, materials, tooling, and process limits.

Release of New Products

This year was very busy with new product development. Among the releases were reinforced steering wheels, antique parking lanterns, improvements to the light bar, half moon steering gears, and rear bushings.

This year was very busy with new product development. Among the releases were reinforced steering wheels, antique parking lanterns, improvements to the light bar, half moon steering gears, and rear bushings.

The larger steering wheel, originally released by Crue Cut in the late sixties, reduces steering effort for younger drivers and improves durability through added gusseting. Foam based tooling allowed us to produce high quality parts with minimal finishing and low tooling costs.

Antique parking lanterns were developed after user requests, though demand has proven limited. Several iterations were required to achieve proper casting thickn ess and finish.

ess and finish.

The improved light bar remains a challenge due to filling and gas issues, though development continues.

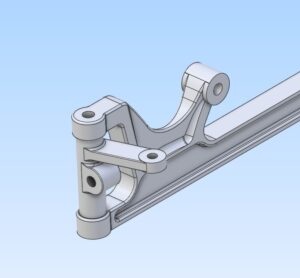

The half moon steering gear was developed as a durable replacement using a laser cut steel design with a welded boss and pressed brass bushing. Rear bushings continue to be offered as replacements for commonly worn or missing originals.

New Products in the Works

We are developing replacement front axles and spindles using nodular spheroidal iron, as cast iron is difficult and CNC machining alone is not cost effective. These parts are expected to be available in the coming year.

An electric conversion kit is also in development. This kit allows users to replace the gas engine with an electric motor using existing transmission components, reducing exposure to gasoline fumes while keeping the system simple.

Looking Ahead

One of our goals is to better showcase what we offer. Many basic questions still appear on forums about where to buy wheels, hubs, fenders, lighting, and steering components. These questions will be addressed through a planned video series on YouTube in the coming year.

In summary, this year was defined by resilience, reinvestment, and a commitment to service. Go Kart Guru remains focused on craftsmanship, honest partnerships, and helping enthusiasts keep their vintage go karts running, guided by the belief that a good reputation, thoughtful innovation, and respect for others matter more than short term profit.