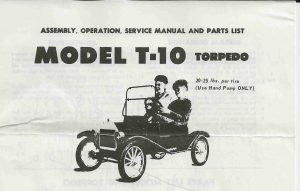

You may have recently just purchased a McDonough model-t go kart that came with wooden spoked wheels. The rustic look, the spiffy looking appearance and the overall authenticity are captivating and almost deemed essential, especially for the meticulous restorer.

You may have recently just purchased a McDonough model-t go kart that came with wooden spoked wheels. The rustic look, the spiffy looking appearance and the overall authenticity are captivating and almost deemed essential, especially for the meticulous restorer.

The original Henry Ford Model-T came with wooden spokes, so it makes sense that t

The potential for these Vintage McDonoughs (granted this is a Mini Kar…) is incredible. This particular unit is a Tow Truck version, complete with duallies! Several of our components are used on this gokart-restoration-upgrade.

he original release of McDonough ¼ scale Model-T 10’s, back in the 1950’s came with wooden spokes also. Each wheel was handled with care and each rim was fitted to a custom set of wooden spokes to get the fit right.

I know, I have an original Model-T 10 set of wooden wheels, and they are cool…but.

The but… is what this article is about. Unfortunately, in product development realities set in, and the reality is not just cost, it is reliability and safety.

The major complaint about wooden spoked wheels is the durability and most especially the strength of the wheel, especially during cornering.

If anyone has used an umbrella they will understand what I am talking about. An umbrella relies on the tension of the umbrella being out, with the center being pressed up into the frame and locked. The lock is what keeps the umbrella from collapsing.

If anyone has used an umbrella they will understand what I am talking about. An umbrella relies on the tension of the umbrella being out, with the center being pressed up into the frame and locked. The lock is what keeps the umbrella from collapsing.

In wooden wheel, the way they are assembled is that all the spokes are custom fit into the rim and placed in a high position, like when the umbrella is down. The hub, and the spokes then are pressed down so that they are flat. This puts a compressive load on the hub-spoke interface, but at the same time puts tension on the rim. The position of the spokes is then kept in place with two plates that are bolted to the hub. The plates provide a compressive load on the center of the hub preventing the spoke assembly from moving outward or ax ially outward.

ially outward.

This latter step, is critical, and is most often overlooked. The bolts and the plates need to be tight to keep the spoke assembly rigid. If the bolts get lose or the spokes get compromised (ie brittle, soft, or split) the danger of a wheel collapsing increases almost exponentially. I mean it doesn’t take much to make wooden wheel assembly to fail.

Knowing this complexity, each wheel assembly must be fitted by hand, and tweeked by hand. That means that simple buy off the internet spokes will not be available by anyone because of the danger involved. The best that can be accomplished to send the rim-spokes-keepers to a custom shop and have them fit the wheel-(New Custom-Spokes) together.

This liability of failure dogged the McDonough company and as a result they switched out to more dependable and durable options, such as the aluminum wheel and later the plastic wheel (though it  too proved to be a problem especially with age as they too brake, but more do to weathering.)

too proved to be a problem especially with age as they too brake, but more do to weathering.)

The other issue, is the cost. Even if it were possible to get a custom set of spokes, they would cost in the neighborhood of 10-12$ each. There are 12 spokes. The math is $144 just for spokes. Then they need to be custom fit. After you have spent you money shipping the rim to the guy ($30) having him fit them to the rim ($70) and then ship back to you ($30), your total cost is around $274 per wheel.

Believe me, I have talked to many a wood-be customer and they have walked away from that option just because of the cost. You can buy new aluminum wheels for less that each.

If you are a true restorer and want the authenticity, I get it, however be warned to restore as original has its costs. If you are restoring it just to ride it, look into different but not selling the farm options.

As a side note, on this site we do sell the aluminum rims, however I must clarify, they are not just any old aluminum rim, they are designed to be authentic and dutifully mimic the original plastic wheels that were introduced back in the late 1960’s.

The plastic wheels were designed to look like the original Henry Ford Model T car wheels, complete with clamp bumps and similar spoke designs. Later in the production cycle of the plastic rims, curved inlets were made to the tops of the spokes to the rim interface to make the molding more reliable and the rims stronger. The original plastic rims had no radii to the spoke rim interface and were prone to crack after use. Additionally, they were a failure zone in plastic injection molding and would cause manufacturing rejection rates to be unacceptable. So the interface was introduced for plastic flow-stress relief.

The plastic wheels were designed to look like the original Henry Ford Model T car wheels, complete with clamp bumps and similar spoke designs. Later in the production cycle of the plastic rims, curved inlets were made to the tops of the spokes to the rim interface to make the molding more reliable and the rims stronger. The original plastic rims had no radii to the spoke rim interface and were prone to crack after use. Additionally, they were a failure zone in plastic injection molding and would cause manufacturing rejection rates to be unacceptable. So the interface was introduced for plastic flow-stress relief.

Finall

Finall y, our ri

y, our ri ms are designed to mimic this change. So what usually occurs is someone has to replace a plastic rim, and they don’t want the one replaced rim to stick out. These aluminum rims can be painted and hardly even noticeable to the untrained eye.

ms are designed to mimic this change. So what usually occurs is someone has to replace a plastic rim, and they don’t want the one replaced rim to stick out. These aluminum rims can be painted and hardly even noticeable to the untrained eye.

The obvious benefit is that the aluminum rims are bullet proof. You will break the gokart before you will break a rim.

If you are interested in what we have to offer for rims visit the following page:

If you are more interested in what possibly we have to offer for other parts, such as headlights, light bars, fenders, or even a more dependable brake system….visit this page:

Model T Go Kart Parts Store (Click on Image to go to store)